1, Hydroxyl darajar: 1 gram polymer polyol ƙunshi hydroxyl (-OH) adadin daidai da adadin milligrams na KOH, naúrar mgKOH/g.

2, Daidai: matsakaicin nauyin kwayoyin halitta na ƙungiyar aiki.

3, Isocyanate abun ciki: abun ciki na isocyanate a cikin kwayoyin halitta

4, Isocyanate index: yana nuna matakin isocyanate wuce haddi a cikin tsarin polyurethane, yawanci wakilta ta harafin R.

5. Sarkar extender: Yana nufin low kwayoyin nauyi alcohols da amines da za su iya mika, fadada ko samar sarari cibiyar sadarwa crosslinks na kwayoyin halitta.

6. Hard segment: Sashin sarkar da aka kafa ta hanyar amsawar isocyanate, sarkar sarkar da crosslinker a kan babban sarkar kwayoyin polyurethane, kuma waɗannan kungiyoyi suna da ƙarfin haɗin kai, girman sararin samaniya da kuma mafi girma.

7, Yanki mai laushi: carbon carbon main sarkar polymer polyol, sassauci yana da kyau, a cikin babban sarkar polyurethane don sashin sarkar sassauƙa.

8, Hanyar mataki daya: yana nufin oligomer polyol, diisocyanate, sarkar tsawo da mai kara kuzari gauraye a lokaci guda bayan kai tsaye allura a cikin mold, a wani zafin jiki curing gyare-gyaren hanya.

9, Hanyar Prepolymer: Na farko oligomer polyol da diisocyanate prepolymerization dauki, don samar da karshen NCO tushen polyurethane prepolymer, zuba sa'an nan prepolymer dauki tare da sarkar extender, shiri na polyurethane elastomer hanya, da ake kira prepolymer hanya.

10, Semi-prepolymer Hanyar: Bambanci tsakanin Semi-prepolymer hanya da prepolymer hanya shi ne cewa wani ɓangare na polyester polyol ko polyether polyol an kara zuwa prepolymer a cikin nau'i na cakuda tare da sarkar extender, mai kara kuzari, da dai sauransu.

11, Reaction injection molding: Har ila yau aka sani da Reaction Injection Molding RIM (Reaction Injection Molding), ana auna shi da oligomers tare da ƙananan nauyin kwayoyin halitta a cikin ruwa, gauraye nan da nan kuma a allura a cikin mold a lokaci guda, da kuma saurin amsawa a cikin mold cavity, kwayoyin nauyin kayan yana ƙaruwa da sauri. Tsari don ƙirƙirar sabbin polymers gabaɗaya tare da sabbin sifofi na ƙungiyar a cikin maɗaukakin gudu.

12, Fihirisar Kumfa: wato, adadin sassan ruwa da ake amfani da su a cikin sassa 100 na polyether an bayyana shi azaman ma'anar kumfa (IF).

13, Maganin Kumfa: Gabaɗaya yana nufin amsawar ruwa da isocyanate don samar da urea da aka maye gurbinsu da sakin CO2.

14, Gel dauki: gabaɗaya yana nufin samuwar halayen carbamate.

15, Gel lokaci: a karkashin wasu yanayi, da ruwa abu don samar da gel bukatar lokaci.

16, Lokacin Milky: a ƙarshen yanki na I, abin mamaki na madara ya bayyana a cikin cakuda polyurethane na ruwa. Wannan lokacin ana kiran lokacin cream a cikin ƙarni na kumfa polyurethane.

17, Sarkar faɗaɗa coefficient: yana nufin rabon adadin amino da ƙungiyoyin hydroxyl (raka'a: mo1) a cikin sassan sassan sarkar (ciki har da haɗaɗɗen sarkar mai shimfiɗa) zuwa adadin NCO a cikin prepolymer, wato, lambar tawadar Allah. (madaidaicin lamba) rabo na ƙungiyar hydrogen mai aiki zuwa NCO.

18, Low unsaturation polyether: yafi ga PTMG ci gaban, PPG farashin, unsaturation rage zuwa 0.05mol / kg, kusa da yi na PTMG, ta yin amfani da DMC kara kuzari, babban iri-iri na Bayer Acclaim jerin kayayyakin.

19, Ammoniya ester grade mai ƙarfi: samar da ƙwayar polyurethane don yin la'akari da ƙarfin rushewa, ƙimar haɓakawa, amma samar da polyurethane da aka yi amfani da shi a cikin ƙaura, ya kamata a mayar da hankali kan la'akari da nauyin NC0 mai nauyi a cikin polyurethane. Abubuwan da za a iya amfani da su kamar su alcohols da ether alcohols waɗanda ke amsawa tare da ƙungiyoyin NCO ba za a iya zaɓar su ba. Mai ƙarfi ba zai iya ƙunsar ƙazanta irin su ruwa da barasa ba, kuma ba zai iya ƙunsar abubuwan alkali ba, wanda zai sa polyurethane ya lalace.

Ba a ba da izinin maganin ester ya ƙunshi ruwa ba, kuma dole ne ya ƙunshi free acid da alcohols, wanda zai amsa tare da kungiyoyin NCO. Maganin ester da aka yi amfani da shi a cikin polyurethane ya kamata ya zama "ammoniya ester grade solvent" tare da babban tsarki. Wato, sauran ƙarfi yana amsawa tare da wuce haddi na isocyanate, sa'an nan kuma an ƙayyade adadin isocyanate wanda bai dace ba tare da dibutylamine don gwada ko ya dace da amfani. Ka'idar ita ce amfani da isocyanate bai dace ba, saboda yana nuna cewa ruwan da ke cikin ester, barasa, acid uku zai cinye jimlar adadin isocyanate, idan an bayyana adadin gram na sauran ƙarfi da ake buƙata don cinye rukunin leqNCO, darajar ne mai kyau kwanciyar hankali.

Isocyanate daidai da ƙasa da 2500 ba a yi amfani da shi azaman ƙarfi na polyurethane.

Polarity na sauran ƙarfi yana da tasiri mai girma akan amsawar samuwar guduro. Mafi girma da polarity, da sannu a hankali da dauki, kamar toluene da methyl ethyl ketone bambanci na 24 sau, wannan ƙarfi kwayoyin polarity ne babba, zai iya samar da wani hydrogen bond tare da barasa hydroxyl kungiyar da kuma sa dauki jinkirin.

Polychlorinated ester ƙarfi ne mafi alhẽri a zabi aromatic ƙarfi, su dauki gudun ne sauri fiye da ester, ketone, kamar xylene. Yin amfani da magungunan ester da ketone na iya tsawanta rayuwar sabis na polyurethane mai rassa biyu a lokacin ginawa. A cikin samar da sutura, zaɓin "ƙaunar ammonia-grade" da aka ambata a baya yana da amfani ga masu daidaitawa da aka adana.

Abubuwan kaushi na Ester suna da ƙarfi mai ƙarfi, matsakaicin volatilization rate, ƙarancin guba kuma ana amfani da su sosai, cyclohexanone kuma ana amfani da ƙari, masu kaushi na hydrocarbon suna da ƙarancin narkewar ƙarfi, ƙarancin amfani da shi kaɗai, da ƙarin amfani tare da sauran kaushi.

20, Wakilin busawa na jiki: wakili mai busawa na jiki shine kumfa pores suna samuwa ta hanyar canjin yanayin jiki na wani abu, wato, ta hanyar fadada iskar gas, rashin daidaituwa na ruwa ko rushewar m.

21, Chemical hurawa jamiái: sinadaran hurawa jamiái su ne wadanda za su iya saki iskar gas kamar carbon dioxide da nitrogen bayan dumama bazuwa, da kuma samar da lafiya pores a cikin polymer abun da ke ciki na fili.

22, Tsallakewa ta jiki: akwai wasu sarƙoƙi masu wuya a cikin sarkar taushin polymer, kuma sarkar mai wuya tana da kaddarorin jiki iri ɗaya kamar na roba mai ɓarna bayan haɗewar sinadarai a yanayin zafi ƙasa da wurin laushi ko narkewa.

23, Chemical crosslinking: yana nufin aiwatar da haɗa manyan sarƙoƙi na ƙwayoyin cuta ta hanyar haɗin sinadarai a ƙarƙashin aikin haske, zafi, radiation mai ƙarfi, ƙarfin injin, duban dan tayi da jami'an crosslinking don samar da hanyar sadarwa ko tsarin tsarin polymer.

24, Fihirisar Kumfa: adadin sassan ruwa daidai da sassa 100 na polyether an bayyana shi azaman ma'aunin kumfa (IF).

25. Wadanne nau'ikan isocyanates ne aka fi amfani da su cikin tsari?

A: Aliphatic: HDI, alicyclic: IPDI,HTDI,HMDI, Aromatik: TDI,MDI,PAPI,PPDI,NDI.

26. Wadanne nau'ikan isocyanates ne aka fi amfani da su? Rubuta tsarin tsari

A: Toluene diisocyanate (TDI), diphenylmethane-4,4 '-diisocyanate (MDI), polyphenylmethane polyisocyanate (PAPI), liquefied MDI, hexamethylene-diisocyanate (HDI).

27. Ma'anar TDI-100 da TDI-80?

A: TDI-100 ya ƙunshi toluene diisocyanate tare da tsarin 2,4; TDI-80 yana nufin cakuda wanda ya ƙunshi 80% toluene diisocyanate na tsarin 2,4 da 20% na tsarin 2,6.

28. Menene halayen TDI da MDI a cikin haɗin kayan polyurethane?

A: Reactivity don 2,4-TDI da 2,6-TDI. Reactivity na 2,4-TDI sau da yawa mafi girma fiye da na 2,6-TDI, saboda 4-matsayi NCO a cikin 2,4-TDI yana da nisa daga matsayi na 2 NCO da methyl, kuma akwai kusan kusan. babu juriya mai mahimmanci, yayin da NCO na 2,6-TDI ya shafi tasirin tasirin ortho-methyl.

Ƙungiyoyin NCO guda biyu na MDI sun yi nisa kuma babu masu maye a kusa da su, don haka ayyukan NCO guda biyu yana da girma. Ko da NCO ɗaya ya shiga cikin amsawa, aikin sauran NCO ya ragu, kuma aikin yana da girma a gaba ɗaya. Saboda haka, reactivity na MDI polyurethane prepolymer ya fi girma fiye da na TDI prepolymer.

29.HDI, IPDI, MDI, TDI, NDI wanne daga cikin juriya mai launin rawaya ya fi kyau?

A: HDI (nasa ne na diisocyanate yellow aliphatic diisocyanate maras canzawa), IPDI (wanda aka yi da resin polyurethane tare da ingantaccen kwanciyar hankali da juriya na sinadarai, gabaɗaya ana amfani da su don kera manyan abubuwan da ba su canza launi na polyurethane ba).

30. Manufar gyaran MDI da hanyoyin gyare-gyare na kowa

A: Liquefied MDI: Ƙimar da aka yi amfani da ita: MDI mai tsabta mai tsabta shine MDI wanda aka gyara shi, wanda ya shawo kan wasu lahani na MDI mai tsabta (mai ƙarfi a cikin dakin da zafin jiki, narkewa lokacin amfani da, dumama da yawa yana rinjayar aikin), kuma yana ba da tushe ga kewayon da yawa. na gyare-gyare don haɓakawa da haɓaka aikin kayan aikin polyurethane na tushen MDI.

Hanyoyi:

① urethane wanda aka gyara MDI mai ruwa.

② carbodiimide da uretonimine da aka gyara MDI mai liquefied.

31. Wadanne nau'ikan polyols na polymer ne aka fi amfani da su?

A: polyester polyol, polyether polyol

32. Nawa hanyoyin samar da masana'antu nawa ne don polyester polyols?

A: Hanyar narkewar injin B, Hanyar narkewar iskar gas mai ɗaukar kaya C, hanyar distillation azeotropic

33. Menene sifofi na musamman akan kashin bayan kwayar halitta na polyester da polyether polyols?

A: Polyester polyol: Macromolecular barasa fili dauke da wani ester kungiyar a kan kwayoyin kashin baya da kuma wani hydroxyl kungiyar (-OH) a kan karshen kungiyar. Polyether polyols: Polymers ko oligomers dauke da ether bonds (-O-) da kuma ƙarshen makada (-Oh) ko amine kungiyoyin (-NH2) a cikin tsarin kashin baya na kwayoyin.

34. Menene nau'ikan polyether polyols gwargwadon halayensu?

A: Polyether polyols mai aiki sosai, polyether polyols da aka dasa, polyether polyols na wuta, polyether polyols heterocyclic modified, polytetrahydrofuran polyols.

35. Nawa nau'ikan polyethers na yau da kullun akwai a cewar wakilin farawa?

A: Polyoxide propylene glycol, polyoxide propylene triol, m kumfa polyether polyol, low unsaturation polyether polyol.

36. Menene bambanci tsakanin hydroxy-terminated polyethers da amine-terminated polyethers?

Aminoterminated polyethers su ne polyoxide allyl ethers wanda aka maye gurbin ƙarshen hydroxyl da ƙungiyar amin.

37. Wadanne nau'ikan abubuwan kara kuzari na polyurethane aka fi amfani da su? Wadanne nau'ikan da aka saba amfani da su sun hada?

A: Amine masu kara kuzari, nau'ikan da aka saba amfani da su sune: triethylenediamine, dimethylethanolamine, n-methylmorpholine, N, n-dimethylcyclohexamine

Metallic alkyl mahadi, nau'in da aka saba amfani da su sune: organotin catalysts, ana iya raba su zuwa octoate mai ban mamaki, stannous oleate, dibutyltin dilaurate.

38. Wadanne nau'ikan sarkar polyurethane da aka saba amfani da su ko crosslinkers?

A: Polyols (1, 4-butanediol), alicyclic alcohols, aromatic alcohols, diamines, barasa amines (ethanolamine, diethanolamine)

39. Hanyar amsawa na isocyanates

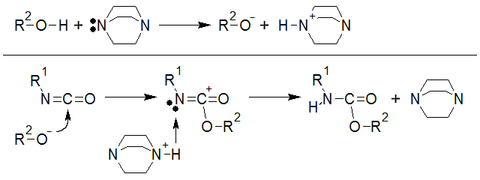

A: Halin isocyanates tare da mahadi masu aiki na hydrogen suna haifar da su ta hanyar cibiyar nucleophilic na kwayoyin halitta mai aiki na hydrogen da ke kaiwa NCO tushen carbon atom. Hanyar amsawa shine kamar haka:

40. Ta yaya tsarin isocyanate ya shafi reactivity na kungiyoyin NCO?

A: Electronegativity na ƙungiyar AR: idan ƙungiyar R ƙungiya ce mai ɗaukar electron, ƙarfin girgije na electron na C atom a cikin rukunin -NCO yana da ƙasa, kuma yana da rauni ga harin nucleophiles, wato, shi. ya fi sauƙi don aiwatar da halayen nucleophilic tare da alcohols, amines da sauran mahadi. Idan R shine ƙungiyar masu ba da gudummawa ta lantarki kuma ana canjawa wuri ta hanyar gajimare na lantarki, ƙarancin wutar lantarki na C atom a cikin ƙungiyar -NCO zai ƙaru, yana mai da shi ƙasa da rauni ga harin nucleophiles, kuma ikon amsawa tare da mahaɗan hydrogen masu aiki zai kasance. rage. B. Sakamakon ƙaddamarwa: Saboda diisocyanate aromatic ya ƙunshi ƙungiyoyin NCO guda biyu, lokacin da na farko -NCO gene ya shiga cikin amsawa, saboda tasirin haɗin gwiwa na zobe na aromatic, ƙungiyar -NCO wanda ba ya shiga cikin amsawa zai taka rawar. na ƙungiyar masu ɗaukar electron, ta yadda aikin amsawar ƙungiyar NCO ta farko ta inganta, wanda shine tasirin shigarwa. C. steric sakamako: A cikin kwayoyin diisocyanate aromatic, idan ƙungiyoyi biyu -NCO sun kasance a cikin zobe na aromatic a lokaci guda, to, tasirin ƙungiyar NCO ɗaya akan sake kunnawa na sauran ƙungiyar NCO sau da yawa. Koyaya, idan ƙungiyoyin NCO guda biyu suna cikin zoben ƙamshi daban-daban a cikin kwaya ɗaya, ko kuma an raba su da sarƙoƙi na hydrocarbon ko zoben kamshi, hulɗar da ke tsakanin su kaɗan ce, kuma tana raguwa tare da haɓakar tsawon sarkar hydrocarbon ko ƙara yawan zoben ƙanshi.

41. Nau'in mahaɗan hydrogen masu aiki da NCO reactivity

A: Aliphatic NH2> Ƙungiyar aromatic Bozui OH> Ruwa> Na biyu OH> Phenol OH> Ƙungiyar Carboxyl> Sauya urea> Amido> Carbamate. (Idan yawan girgije na lantarki na cibiyar nucleophilic ya fi girma, electronegativity ya fi karfi, kuma aikin amsawa tare da isocyanate ya fi girma kuma saurin amsawa yana da sauri; In ba haka ba, aikin yana da ƙasa.)

42. Tasirin mahadi na hydroxyl akan reactivity tare da isocyanates

A: The reactivity na aiki hydrogen mahadi (ROH ko RNH2) yana da alaka da kaddarorin R, a lokacin da R ne wani electron-jarar kungiyar (low electronegativity), yana da wuya a canja wurin hydrogen atoms, da kuma dauki tsakanin aiki hydrogen mahadi da kuma NCO ya fi wahala; Idan R shine madadin ba da gudummawar lantarki, ana iya inganta reactivity na mahaɗan hydrogen masu aiki tare da NCO.

43. Menene amfanin isocyanate dauki tare da ruwa

A: Yana daya daga cikin halayen asali a cikin shirye-shiryen kumfa polyurethane. Halin da ke tsakanin su da farko yana samar da sinadarin carbamic acid mara kyau, wanda daga nan ya rushe zuwa CO2 da amines, kuma idan isocyanate ya wuce gona da iri, sakamakon amine yana amsawa tare da isocyanate don samar da urea.

44. A cikin shirye-shiryen polyurethane elastomers, abun ciki na ruwa na polyols polymer ya kamata a sarrafa shi sosai.

A: Ba a buƙatar kumfa a cikin elastomers, coatings da zaruruwa, don haka abun ciki na ruwa a cikin albarkatun kasa dole ne a sarrafa sosai, yawanci kasa da 0.05%.

45. Bambance-bambance a cikin tasirin catalytic na amine da tin catalysts akan halayen isocyanate.

A: Manyan amine masu haɓakawa suna da haɓakar haɓakar haɓakar haɓakar haɓakar haɓakar isocyanate tare da ruwa, yayin da masu haɓakar tin suna da ingantaccen ƙarfin kuzari don ɗaukar isocyanate tare da rukunin hydroxyl.

46. Me yasa za'a iya ɗaukar resin polyurethane azaman toshe polymer, kuma menene halayen tsarin sarkar?

Amsa: Saboda sashin sarkar na resin polyurethane yana kunshe da sassa masu wuya da taushi, sashi mai wuya yana nufin sashin sarkar da aka kafa ta hanyar amsawar isocyanate, sarkar sarkar da crosslinker a kan babban jerin kwayoyin polyurethane, kuma waɗannan kungiyoyi suna da haɗin kai mafi girma. makamashi, mafi girman girman sararin samaniya da mafi girman rigidity. Sashi mai laushi yana nufin babban sarkar carbon-carbon polymer polyol, wanda ke da sassauci mai kyau kuma yanki ne mai sassauƙa a cikin babban sarkar polyurethane.

47. Menene abubuwan da suka shafi kaddarorin kayan polyurethane?

A: Ƙungiya haɗin gwiwa makamashi, hydrogen bond, crystallinity, crosslinking digiri, kwayoyin nauyi, wuya sashi, taushi sashi.

48. Menene albarkatun kasa sune sassa masu laushi da wuya a kan babban sarkar kayan polyurethane

A: Sashin mai laushi ya ƙunshi polyols oligomer (polyester, polyether diols, da dai sauransu), kuma sashi mai wuya ya ƙunshi polyisocyanates ko haɗin su tare da ƙananan sarkar kwayoyin halitta.

49. Ta yaya sassa masu laushi da sassa masu wuya suka shafi kayan kayan polyurethane?

A: Sashi mai laushi: (1) Nauyin kwayoyin halitta na sassa masu laushi: suna zaton cewa nauyin kwayoyin halitta na polyurethane daidai ne, idan ɓangaren mai laushi shine polyester, ƙarfin polyurethane zai karu tare da karuwar nauyin kwayoyin halitta. polyester diol; Idan sashi mai laushi shine polyether, ƙarfin polyurethane yana raguwa tare da haɓaka nauyin kwayoyin halitta na polyether diol, amma haɓaka yana ƙaruwa. (2) Ƙaƙƙarfan ƙira na sassa mai laushi: Yana da babbar gudummawa ga kristal na layin sarkar polyurethane na layi. Gabaɗaya, crystallization yana da fa'ida don haɓaka aikin samfuran polyurethane, amma wani lokacin crystallization yana rage ƙarancin zafin jiki na kayan abu, kuma kristal polymer sau da yawa ba shi da kyau.

Yanki mai wuya: Bangaren sarkar mai wuya yawanci yana rinjayar laushi da narkewar zafin jiki da halayen zafin jiki na polymer. Polyurethanes da aka shirya ta isocyanates na aromatic sun ƙunshi zoben aromatic masu ƙarfi, don haka ƙarfin polymer a cikin ɓangaren wuya yana ƙaruwa, kuma ƙarfin abu gabaɗaya ya fi na aliphatic isocyanate polyurethane, amma juriya ga lalatawar ultraviolet ba shi da kyau, kuma yana da sauƙin rawaya. Aliphatic polyurethane ba sa rawaya.

50. Polyurethane kumfa rarraba

A: (1) kumfa mai laushi da kumfa mai laushi, (2) babban kumfa da ƙananan kumfa, (3) nau'in polyester, nau'in nau'in polyether, (4) nau'in TDI, nau'in nau'in MDI, (5) kumfa polyurethane da polyisocyanurate kumfa, (6) Hanyar mataki daya da samar da hanyar prepolymerization, hanyar ci gaba da samar da lokaci mai tsawo, (8) toshe kumfa da kumfa mai gyare-gyare.

51. Abubuwan halayen asali a cikin shirye-shiryen kumfa

A: Yana nufin amsawar -NCO tare da -OH, -NH2 da H2O, kuma lokacin da ake amsawa tare da polyols, ''gel reaction'' a cikin tsarin kumfa gabaɗaya yana nufin haɓakar haɓakar carbamate. Saboda albarkatun kumfa yana amfani da kayan aiki masu yawa, ana samun hanyar sadarwa mai haɗin gwiwa, wanda ke ba da damar tsarin kumfa don gel da sauri.

Halin kumfa yana faruwa a cikin tsarin kumfa tare da kasancewar ruwa. Abin da ake kira "ɗaukar kumfa" gabaɗaya yana nufin ɗaukar ruwa da isocyanate don samar da urea da aka maye gurbinsu da sakin CO2.

52. Nucleation inji na kumfa

Danyen abu yana amsawa a cikin ruwa ko kuma ya dogara da yanayin zafin da ake samarwa don samar da wani abu mai iskar gas kuma ya canza iskar gas. Tare da ci gaba da amsawa da kuma samar da babban adadin zafi mai zafi, yawan adadin gas da haɓakawa ya karu ci gaba. Lokacin da yawan iskar gas ya ƙaru fiye da ma'aunin jikewa, kumfa mai ɗorewa ta fara samuwa a cikin lokacin bayani kuma ya tashi.

53. Matsayin kumfa stabilizer a cikin shirye-shiryen polyurethane kumfa

A: Yana da tasirin emulsification, don haka ana inganta haɓakar juna tsakanin sassan kayan kumfa; Bayan ƙari na silicone surfactant, saboda yana rage girman tashin hankali γ na ruwa, ƙara yawan makamashin da ake buƙata don watsawar iskar gas yana raguwa, don haka iska da aka tarwatsa a cikin albarkatun kasa zai iya haifar da raguwa a lokacin tsarin hadawa, wanda zai iya haifar da raguwa a lokacin hadawa. yana taimakawa wajen samar da ƙananan kumfa kuma yana inganta kwanciyar hankali na kumfa.

54. Tsarin kwanciyar hankali na kumfa

A: Bugu da kari na dace surfactants ne m ga samuwar lafiya kumfa watsawa.

55. Tsarin tsari na buɗaɗɗen kumfa na cell da rufaffiyar kumfa

A: Tsarin tsari na kumfa mai buɗewa: A mafi yawan lokuta, lokacin da akwai babban matsa lamba a cikin kumfa, ƙarfin bangon kumfa da aka kafa ta hanyar gel ba ta da girma, kuma fim din bango ba zai iya jure wa shimfidawa ba. Ta hanyar hawan iskar gas, an jawo fim ɗin bangon kumfa, kuma iskar gas ɗin ya tsere daga fashewa, yana samar da kumfa mai bude-kwayoyin.

Ƙirƙirar kumfa mai rufaffiyar ƙwayar cuta: Don tsarin kumfa mai wuya, saboda amsawar polyether polyols tare da ayyuka masu yawa da ƙananan nauyin kwayoyin halitta tare da polyisocyanate, saurin gel yana da sauri, kuma gas a cikin kumfa ba zai iya karya bangon kumfa ba. , don haka samar da rufaffiyar-cell kumfa.

56. Tsarin kumfa na wakili na kumfa na jiki da kuma sinadaran kumfa

A: Wakilin busawa na jiki: Wakilin busawa na jiki shine kumfa pores suna samuwa ta hanyar canjin yanayin jiki na wani abu, wato, ta hanyar fadada iskar gas, rashin daidaituwa na ruwa ko rushewar m.

Abubuwan hurawa sinadarai: Sinadarai masu busawa sune mahadi waɗanda, lokacin da zafi ya lalace, suna fitar da iskar gas kamar carbon dioxide da nitrogen kuma suna samar da pores masu kyau a cikin abun da ke ciki na polymer.

57. Hanyar shiri na kumfa polyurethane mai laushi

A: Hanyar mataki daya da hanyar prepolymer

Hanyar Prepolymer: wato, polyether polyol da wuce haddi TDI dauki aka sanya a cikin wani prepolymer dauke da free NCO kungiyar, sa'an nan kuma gauraye da ruwa, mai kara kuzari, stabilizer, da dai sauransu, don yin kumfa. Hanyar mataki ɗaya: Ana haɗa nau'ikan albarkatun ƙasa kai tsaye a cikin mahaɗin kai ta hanyar lissafi, kuma ana yin mataki da kumfa, wanda za'a iya raba shi zuwa ci gaba da ɗan lokaci.

58. Halayen kumfa a kwance da kumfa a tsaye

Hanyar farantin madaidaicin ma'auni: halin yin amfani da babban takarda da farantin murfin saman. Hanyar zubar da ruwa: ana nuna shi ta hanyar amfani da tsagi mai ambaliya da farantin saukar da bel mai ɗaukar nauyi.

Halayen kumfa a tsaye: zaku iya amfani da ƙaramin kwarara don samun babban yanki na giciye na tubalan kumfa, kuma galibi ana amfani da injin kumfa a kwance don samun sashe iri ɗaya na toshe, matakin kwarara shine sau 3 zuwa 5 girma fiye da na tsaye. kumfa; Saboda babban ɓangaren giciye na toshe kumfa, babu fata na sama da ƙasa, kuma fatar gefen kuma tana da bakin ciki, don haka asarar yankewa ta ragu sosai. Kayan aiki yana rufe ƙaramin yanki, tsayin shuka yana kusan 12 ~ 13m, kuma farashin saka hannun jari na shuka da kayan aikin ya yi ƙasa da na tsarin kumfa a kwance; Yana da sauƙi don maye gurbin hopper da samfurin don samar da jikin kumfa na silindical ko rectangular, musamman maɗaurin kumfa don yankan jujjuya.

59. Mahimman mahimman bayanai na zaɓin albarkatun ƙasa don shirye-shiryen kumfa mai laushi

A: Polyol: polyether polyol ga talakawa block kumfa, kwayoyin nauyi ne kullum 3000 ~ 4000, yafi polyether triol. Polyether triol tare da nauyin kwayoyin halitta na 4500 ~ 6000 ana amfani dashi don babban kumfa mai juriya. Tare da haɓakar nauyin kwayoyin halitta, ƙarfin ƙarfi, haɓakawa da haɓakar kumfa yana ƙaruwa. Reactivity na irin wannan polyethers ya ragu. Tare da haɓaka aikin digiri na polyether, halayen yana haɓaka haɓaka, haɓakar giciye na polyurethane yana ƙaruwa, taurin kumfa yana ƙaruwa, haɓakar haɓaka yana raguwa. Isocyanate: Kayan albarkatun isocyanate na polyurethane taushi toshe kumfa shine yafi toluene diisocyanate (TDI-80). Ƙananan ƙananan aiki na TDI-65 ana amfani dashi kawai don polyester polyurethane kumfa ko kumfa na polyether na musamman. Mai haɓakawa: Fa'idodin kumfa mai laushi mai laushi za a iya raba kusan kashi biyu: ɗaya shine mahadi na organometallic, caprylate mai ƙarfi shine mafi yawan amfani; Wani nau'in shine amines na uku, wanda akafi amfani dashi azaman dimethylaminoethyl ethers. Foam stabilizer: A polyester polyurethane babban kumfa, wadanda ba siliki surfactants ake yafi amfani, kuma a polyether girma kumfa, organosilica-oxidized olefin copolymer ne yafi amfani. Wakilin kumfa: Gabaɗaya, ana amfani da ruwa kawai azaman wakili mai kumfa lokacin da yawan kumfa mai laushi na polyurethane ya fi kilogiram 21 a kowace mita cubic; Ana amfani da ƙananan mahadi masu tafasa irin su methylene chloride (MC) azaman kayan busa taimako kawai a cikin ƙananan ƙira.

60. Tasirin yanayin muhalli a kan kaddarorin jiki na toshe kumfa

A: Sakamakon zafin jiki: tasirin kumfa na polyurethane yana haɓaka yayin da zafin jiki ya tashi, wanda zai haifar da haɗarin ƙonawa mai mahimmanci da wuta a cikin ƙirar ƙira. Tasirin zafi na iska: Tare da karuwar zafi, saboda amsawar ƙungiyar isocyanate a cikin kumfa tare da ruwa a cikin iska, taurin kumfa yana raguwa kuma haɓaka yana ƙaruwa. Ƙarfin ƙarfi na kumfa yana ƙaruwa tare da karuwar ƙungiyar urea. Tasirin matsa lamba na yanayi: Don wannan dabarar, lokacin da ake yin kumfa a tsayi mafi girma, yawancin yana raguwa sosai.

61. Babban bambanci tsakanin tsarin albarkatun kasa da aka yi amfani da shi don sanyi mai laushi mai laushi da kumfa mai zafi mai zafi.

A: The albarkatun kasa amfani a cikin sanyi curing gyare-gyare da high reactivity, kuma babu bukatar waje dumama a lokacin curing, dogara da zafi generated da tsarin, da curing dauki za a iya m kammala a cikin wani gajeren lokaci, da mold iya. a sake shi a cikin 'yan mintoci kaɗan bayan allurar albarkatun kasa. The albarkatun kasa reactivity na zafi curing gyare-gyaren kumfa ne low, da dauki cakuda bukatar da za a mai tsanani tare da mold bayan kumfa a cikin mold, da kuma kumfa samfurin za a iya saki bayan ya cika balagagge a cikin yin burodi tashar.

62. Menene halaye na kumfa mai laushi mai sanyi mai sanyi idan aka kwatanta da kumfa mai zafi

A: ① Tsarin samarwa baya buƙatar zafi na waje, zai iya adana zafi mai yawa; ② Babban sag coefficient (rabo rabe-rabe), kyakkyawan aikin ta'aziyya; ③ Babban koma baya; ④ Kumfa ba tare da jinkirin harshen wuta ba kuma yana da wasu kaddarorin kashe wuta; ⑤ Short sake zagayowar samarwa, na iya ajiye mold, ajiye farashi.

63. Halaye da kuma amfani da taushi kumfa da wuya kumfa bi da bi

A: Halayen kumfa mai laushi: Tsarin tantanin halitta na kumfa mai laushi na polyurethane yana buɗewa. Gabaɗaya, yana da ƙarancin ƙarancin ƙarfi, dawo da mai kyau na roba, ɗaukar sauti, ƙarancin iska, adana zafi da sauran kaddarorin. Amfani: An fi amfani da shi don kayan ɗaki, kayan matashin kai, kayan matashin kujerar abin hawa, kayan kwalliya iri-iri masu laushi masu laushi, masana'antu da kumfa mai laushi na farar hula kuma ana amfani da su azaman kayan tacewa, kayan ruɗar sauti, kayan kariya, kayan ado, kayan marufi. da kayan rufewar thermal.

Halayen kumfa mai ƙarfi: kumfa polyurethane yana da nauyi mai nauyi, ƙayyadaddun ƙayyadaddun ƙarfi da kwanciyar hankali mai kyau; Ayyukan insulation na thermal na polyurethane m kumfa ya fi kyau. Ƙarfin mannewa mai ƙarfi; Kyakkyawan aikin tsufa, tsawon rayuwar sabis na adiabatic; Cakudar amsawa tana da ruwa mai kyau kuma tana iya cika rami ko sarari na hadadden siffa da kyau. The albarkatun kasa na polyurethane wuya kumfa samar da high reactivity, zai iya cimma m curing, kuma zai iya cimma high dace da taro samar a cikin masana'anta.

Amfani: Ana amfani da shi azaman abin rufe fuska don firiji, injin daskarewa, kwantena masu sanyi, ajiyar sanyi, bututun mai da rufin bututun ruwan zafi, bangon gini da rufin rufin, katakon sandwich, da sauransu.

64. Key maki na wuya kumfa dabara zane

A: Polyols: polyether polyols da aka yi amfani da su don ƙayyadaddun kumfa mai wuyar gaske shine gaba ɗaya makamashi mai girma, ƙimar hydroxyl mai girma (ƙananan nauyin kwayoyin halitta) polypropylene oxide polyols; Isocyanate: A halin yanzu, isocyanate da aka yi amfani da shi don kumfa mai wuya shine yafi polymethylene polyphenyl polyisocyanate (wanda aka sani da PAPI), wato, MDI mai laushi da polymerized MDI; Masu busawa: (1) CFC mai busawa (2) HCFC da HFC mai busawa (3) wakili mai busa pentane (4) ruwa; Kumfa stabilizer: The kumfa stabilizer amfani da polyurethane m kumfa tsari ne kullum toshe polymer na polydimethylsiloxane da polyoxolefin. A halin yanzu, mafi yawan kumfa stabilizers sun fi Si-C nau'in; Mai haɓakawa: Mai haɓaka kumfa mai ƙarfi shine galibi amine na uku, kuma ana iya amfani da sinadarin organotin a lokuta na musamman; Sauran Additives: Dangane da buƙatun da buƙatun amfani daban-daban na samfuran kumfa mai ƙarfi na polyurethane, masu kashe wuta, masu buɗewa, masu hana hayaki, masu hana tsufa, wakilai na rigakafin mildew, wakilai masu ƙarfi da sauran abubuwan ƙari za a iya ƙara su cikin dabara.

65. Dukan fata gyare-gyaren kumfa shiri manufa

A: kumfa mai hade da fata (ISF), wanda kuma aka sani da kumfa mai fata (self skinning kumfa), kumfa ce ta filastik wacce ke samar da nata fata mai yawa a lokacin kera.

66. Halaye da kuma amfani da polyurethane microporous elastomers

A: Halaye: polyurethane elastomer shine toshe polymer, gabaɗaya ya ƙunshi oligomer polyol sassauƙa mai tsayi mai tsayi sassa sassauƙa, diisocyanate da sarkar mai tsawo don samar da yanki mai wuya, yanki mai wuya da juzu'i na madadin tsari, ƙirƙirar rukunin tsarin maimaitawa. Baya ga ƙunshi ƙungiyoyin ester ammonia, polyurethane na iya samar da haɗin gwiwar hydrogen a ciki da tsakanin kwayoyin halitta, kuma sassa masu laushi da wuya na iya samar da yankuna na microphase kuma suna haifar da rabuwar microphase.

67. Menene babban halayen halayen halayen polyurethane elastomers

A: Halayen ayyuka: 1, ƙarfin ƙarfi da ƙarfi, na iya kasancewa a cikin nau'i mai yawa (Shaw A10 ~ Shaw D75) don kula da haɓaka mai girma; Gabaɗaya, ana iya samun ƙarancin ƙarancin da ake buƙata ba tare da filastik ba, don haka babu matsala da ƙaurawar filastik ta haifar; 2, ƙarƙashin taurin guda ɗaya, ƙarfin ɗaukar nauyi fiye da sauran elastomer; 3, kyakkyawan juriya na lalacewa, juriyar sa shine sau 2 zuwa 10 na roba na halitta; 4. Kyakkyawan juriya na mai da sinadarai; Aromatic polyurethane radiation resistant; Kyakkyawan juriya na iskar oxygen da juriya na ozone; 5, babban tasiri mai tasiri, kyakkyawan juriya na gajiya da juriya mai girgiza, dace da aikace-aikacen gyare-gyare mai girma; 6, ƙarancin zafin jiki yana da kyau; 7, talakawa polyurethane ba za a iya amfani da sama da 100 ℃, amma yin amfani da musamman dabara iya jure 140 ℃ high zafin jiki; 8, gyare-gyare da kuma farashin sarrafawa suna da ƙananan ƙananan.

68. Polyurethane elastomers ana rarraba su bisa ga polyols, isocyanates, matakan masana'antu, da dai sauransu.

A: 1. Bisa ga albarkatun kasa na oligomer polyol, polyurethane elastomers za a iya raba su zuwa nau'in polyester, nau'in polyether, nau'in polyolefin, nau'in polycarbonate, da dai sauransu. 2. Dangane da bambancin diisocyanate, ana iya raba shi zuwa nau'in aliphatic da aromatic elastomers, kuma a raba shi zuwa nau'in TDI, nau'in MDI, nau'in IPDI, nau'in NDI da sauran nau'o'in; Daga tsarin masana'antu, polyurethane elastomers an raba su a al'ada zuwa kashi uku: nau'in simintin gyare-gyare (CPU), thermoplasticity (TPU) da nau'in hadawa (MPU).

69. Menene abubuwan da ke shafar kaddarorin polyurethane elastomer daga mahangar tsarin kwayoyin halitta?

A: Daga ra'ayi na tsarin kwayoyin halitta, polyurethane elastomer shine toshe polymer, gabaɗaya ya ƙunshi oligomer polyols m dogon sarkar taushi sashi, diisocyanate da sarkar tsawo don samar da wani yanki mai wuya, sashi mai wuya da sassauƙa mai laushi madadin tsari, ƙirƙirar maimaitawa. naúrar tsari. Baya ga ƙunshi ƙungiyoyin ester ammonia, polyurethane na iya samar da haɗin gwiwar hydrogen a ciki da tsakanin kwayoyin halitta, kuma sassa masu laushi da wuya na iya samar da yankuna na microphase kuma suna haifar da rabuwar microphase. Wadannan halaye na tsarin suna sa polyurethane elastomers suna da kyakkyawan juriya da tauri, wanda aka sani da "roba mai jurewa sawa".

70. Performance bambanci tsakanin talakawa polyester irin da polytetrahydrofuran ether irin elastomer

A: Kwayoyin polyester sun ƙunshi ƙarin ƙungiyoyin ester na polar (-COO-), waɗanda za su iya samar da haɗin gwiwar hydrogen na intramolecular mai ƙarfi, don haka polyester polyurethane yana da ƙarfi mai ƙarfi, juriya da juriya mai.

Elastomer da aka shirya daga polyether polyols yana da kwanciyar hankali mai kyau na hydrolysis, juriya na yanayi, ƙarancin zafin jiki da juriya na mold. Tushen labarin/Binciken koyon polymer

Lokacin aikawa: Janairu-17-2024